Click pictures to enlarge.

It's mid September. In the UK, this can mean long warm settled days, sadly missed earlier in the year, or violent Atlantic depressions, racing in one after another. Being very busy, and with a list of maintenance items to addrees this winter, we decided to return to Cardiff with Ishtar at the first opportunity.

The weather for the weekend looked good, rain and Force 6 winds on Friday, settling on Saturday with High pressure, sun and Westerly 3s and 4s. Perfect. We decided to remove the head buoy from our mooring, and leave a line attached to the riser chain, dropping that to the sea bed to reduce wear over the winter. Our friend Vince wanted to do likewise on his mooring, and kindly agreed to drive our car back from Dale to Cardiff.

Dale was in a grey mood, overcast, windy and muddy, with a 7.7m tide - the highest, and lowest, I'd ever seen.

[caption id="" align="alignnone" width="300" caption="Low tide"]

[/caption]

We immediately set about the moorings, scraping kelp and laverbread from the buoys, removing seizing wire and undoing shackles. We were sheltered from the mainly Westerly winds, but not from the driving drizzle.

[caption id="" align="alignnone" width="300" caption="Winterising the moorings"]

[/caption]

That took about an hour. Vince and I had coffee and Welsh cakes. Vince liked those, and decided Ishtar would sail faster with less weight, so did his best to ensure we would be unencumbered by excess Welsh Cakes. Thanks, Vince.

Louise wanted to dive before we left, and scrape some of the remaining weed from the hull, again, hopefully speeding our trip.

[caption id="" align="alignnone" width="300" caption="Smile!"]

[/caption]

It wasn't long before she returned to the surface, reporting that the weed was restricted to the waterline, and we'd removed most of that last week. I took Vince ashore, thanked him for his help and he left. By this time, it was pouring with rain, and the wind was howling in the rigging. The pontoon was empty and Dale seemed like a ghost town as the evening faded.

I checked the weather. The high pressure was still there, but by Monday another low would force it down over France, with strong Southwesterlies forecast for Monday. We'd planned to go to Tenby, then Oxwich, across to Porlock and then to Cardiff. Our thinking was that with the huge tides, we would not make any progress at all when it turned against us, so we'd have to make shorter than usual hops up the channel, waiting on the flood.

I remembered hitting a foul tide approaching Milford a couple of years back and checked our pilot (The excellent

Sea guide to Pembrokeshire, by Tom Bennett). The tide turns to run West along South Pembrokeshire and St Govans head two hours before low. That meant an effective 8 hour flood, maybe 9 hours if we punched the last hour before it turned.

Food for thought as we tucked into our curry. The bombay potatoes were mighty hot, just right for a wet autumn evening.

The following morning was sunny, just as forecast with strong Westerlies. We decided to head straight for Oxwich if we could make it, leaving 3 hours before low water at 11:30. We'd hoped to meet friends for a beer at Tenby, but that would have to wait. Coffee and crumpets was followed by a period of stowing everything breakable.

As the time approached, I became much more nervous. The day of rough weather we had encountered after the Ireland trip was till at the back of my mind.

[caption id="" align="alignnone" width="300" caption="Cast off"]

[/caption]

As we left Dale and turned Southwards heading out of the Haven, I nearly turned back. The swells were huge, and the waves crasheing onto St Anne's head brought back frightening memories. I remembered that it was the height of the ebb, with the biggest tide of the year, the Haven disgorging its entire contents into the Bristol channel, and the oncoming wind. Let's see what it's like at Freshwater West, away from the wind over tide.

It calmed off near Crow rock, the swells down to 2m. we were already flying along at 5 and 6 knots under full sail. I could not help wondering at the designers of boats, as Ishtar rose up and over each swell effortlessly, maintaining her speed with the fresh winds. Louise seemed more relaxed, too.

[caption id="" align="alignnone" width="300" caption="At Freshwater West"]

[/caption]

Ishtar picked up speed and I began to relax. With the tide running with us for the next 8 hours, we'd make Oxwich an hour before the flood ended, at around 21:00. With Genoa flapping in the lee of the main as the wind veered Westerly, we dropped the main and ran with the wind.

Staying close in to the cliffs to avoid the St Gowan's shoals, I intended to head away from land before we were close to potential rough water at St Govan's head. The ranges were not firing, and we were glad we were not further out:

[caption id="" align="alignnone" width="300" caption="St Gowan's shoals"]

[/caption]

Louise went below for some rest and I was alone. We'd left our dog, Tigger, with my mum - he will not do his business on the boat, so if we know we will not be going ashore, we don't take him. As the afternoon eased along, and we left Tenby, and Caldey light in our lee, I could just make out The Worm's Head - the start of the Gower peninsula in the distance. I spent the next few hours enjoying the sail as the wind and swells eased.

[caption id="" align="alignnone" width="300" caption="Sun and Sea"]

[/caption]

I love that picture. I've taken similar many, many times. Just the sun and the sea. You can't hear the wind, feel the warmth of the sun, nor smell the salt air, hear the birds, but it still makes me smile.

As Louise returned to the deck, we were well past the Worm's head, and Oxwich was just a few miles ahead.

[caption id="" align="alignnone" width="300" caption="Worm's head, Gower"]

[/caption]

We were soon rounding Oxwich point and bedding in the anchor. The last of the swells dying down as the cool air of September passed over us.

[caption id="" align="alignnone" width="300" caption="Oxwich"]

[/caption]

We switched off the engine - we'd been running it for the last few hours to give an extra boost to our speed as the wind died down. 55 nm covered in just 8 hours. A fraction under 7 Knots average speed over ground. Bristol channel tides can be a help, as well as a hindrance.

Louise rustled up some bangers and mash, with tinned peas and broad beans and thick dark gravy. We would be up at around 02:45, so I thought a beer was a bad idea, despite a magnificent day's sailing, after a very nervous start.

I awoke 5 minutes before the alarm, at 02:40. Low tide was at 03:25, and then we would have approximately 6 1/2 hrs to get as far up the coast towards Cardiff as we could. Monday's forecast was now for Force 6-7 with occasional gusts of gale force. If all went well, we would anchor at Fontygary bay, or even Barry, catch a couple of hours sleep before setting off again about 16:30 to sail the last few miles back to Cardiff Bay.

Louise hauled in the anchor. With no moon, it was very difficult picking our way between used and unused mooring buoys before we cleared the bay at Oxwich. We'd have to head for the West Scar cardinal mark, to avoid the Scarweather and Nash sands before heading up the channel. Wind was Westerly about force 3. A bit stronger would have been nice, but we were not complaining.

She punched the marks into the GPS and wanted to skipper the passage on her own. Fine, I thought, and went below to rest, at least until it was light. I stuck my head out a couple of hours later, and we were making great progress, Nash point just visible in the East.

[caption id="" align="alignnone" width="300" caption="Just before dawn"]

[/caption]

[caption id="" align="alignnone" width="300" caption="Approaching Nash Point"]

[/caption]

I was kept below, with orders not to touch the GPS, nor make any suggestions. Louise wanted to do it all.

[caption id="" align="alignnone" width="300" caption="Stay down there."]

[/caption]

When I was finally allowed on deck, I asked Louise if we would make Barry or Fontygary bay. 'Cardiff' she replied. The GPS was now showing 9 knots SOG. The tidal prediction for this part of the coast was in excess of 5 knots with the huge tide, and we were using it to great effect, the engine now on as well.

[caption id="" align="alignnone" width="300" caption="It's autumn!"]

[/caption]

Familiar ground, now, as we passed Aberthaw:

[caption id="" align="alignnone" width="300" caption="Aberthaw"]

[/caption]

Steepholm, in the distance:

[caption id="" align="alignnone" width="300" caption="Steepholm Island"]

[/caption]

Flatholm, closer,

[caption id="" align="alignnone" width="300" caption="Flatholm Island"]

[/caption]

The GPS told us that we would easily make Cardiff before the tide turned, and we stormed past the Ranie buoy and Northwards towards Penarth:

[caption id="" align="alignnone" width="300" caption="Dinghies racing, Penarth"]

[/caption]

We made the 10:15 lock. Almost exactly 7 hours after leaving Oxwich. The GPS showing 55 nm covered. Yesterday was amazing at nearly 7 knots average, this was almost unbelievable, at nearly 8 knots!

[caption id="" align="alignnone" width="300" caption="Home"]

[/caption]

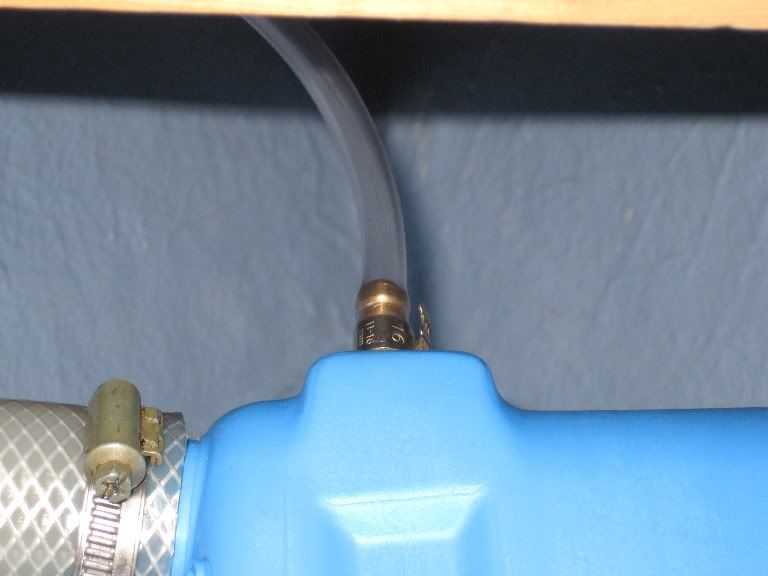

With light winds, clear skies, sun and warmth, we may have made a mistake in leaving Dale so soon, but the split water tank and weedy hull were not the only signs that Ishtar needed some TLC this winter. 15 minutes after locking in, we were tied up on C pontoon, Cardiff Yacht club, and there were plenty of friends about.

Good to be back home.

[/caption]

[/caption] [/caption]

[/caption] [/caption]

[/caption] [/caption]

[/caption]