Then work intervened, and I ended up spending most of the week in Bristol, leaving a huge amount of pressure on Louise. She coped admirably, above and beyond every other woman I know, working night shifts before returning to the boatyard for an hour or two, sleeping in the car before continuing her work. I would never have managed without her.

[caption id="" align="alignnone" width="300" caption="Hero"]

[/caption]

[/caption]I'd cut and pinned all the new engine cables, Louise fitted all the connectors and connected the system up. Lights on, and engine live first time! The tricky bit was fitting 3 x 50mm cables into the '1-2-all' switch, but Louise did a lovely job.

[caption id="" align="alignnone" width="300" caption="Tight fit"]

[/caption]

[/caption]Our friend Vince came to the rescue as well, fitting the new water intake

And doing a beautiful job of splicing in a piece of teak to our rubbing strake, which repleced a rotted piece. Thanks Vince.

[caption id="" align="alignnone" width="300" caption="Vince, repairing our rubbing strake"]

[/caption]

[/caption]With the boat out of the water, security was an important issue. It was vital to ensure that anyone intent on breaking into the boat and stealing our new engine was kept at bay:

[caption id="" align="alignnone" width="300" caption="Beware of the dog"]

[/caption]

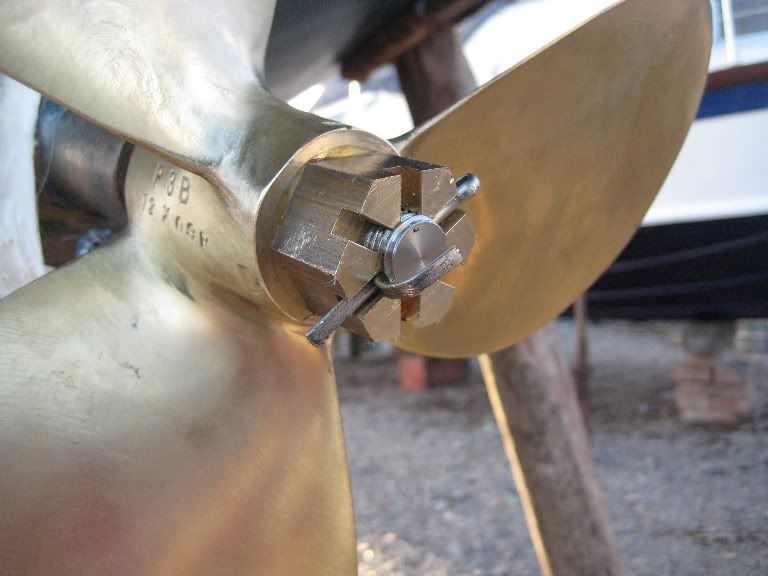

[/caption]We gradually ticked off the jobs, with me doing little bits whenever I could. I broke three De Walt 'Extreme' bits drilling a hole in the prop shaft for a split pin. A simple job, still took nearly 2 hours:

[caption id="" align="alignnone" width="300" caption="Prop shaft hole"]

[/caption]

[/caption]And on with the prop:

Then, suddenly, it was late on Friday evening. Ishtar was being launched at 10:00 on Saturday morning. There were tools and mess everywhere. The fuel lines had still not been fitted, and we'd completely forgotten the through hull fitting for the speed log was leaking, and needed a dab more sikaflex. Louise quickly did it, and picked up a curry on her way home. She'd not slept for 36 hours.